The dark meat is not packed in can as they are not appealing and normally goes for pet food preparations.

3.2.2.1.Filling of cans

Placing a definite quantity of well prepared food into clean cans can be considered as packing or filling. Pork, Beef, poultry meat, mutton. Aquatic animal e.g. In the case of shrimp or clam meat, machine filling is possible. The soluble impurities should not be more than 1.5% and insoluble impurities should not be more than 0.5% when it is used for can filling.

* The counts of halophilic bacteria and pathogenic bacterial spores in salts should be low.

* The salt should have minimum of 98% sodium chloride content, should be of small crystal size for easy dissolution. Blanching results in contraction and curling of shrimp, reduced moisture content, development of firm texture and attractive colouring. crustaceans, marine mammals including whales, fishes such as salmon, tuna, mackerel, sardine, herring, pilchard, pikes, seer, pomfret etc and shellfishes such as crabs, lobsters, shrimps, cuttlefish, clams and green mussels.

Others - processed foods such as condensed milk, soups, baby food and milk powder.

3.1.2.Desirable characteristics of marine products for canning

* The fish should be in fresh condition and should have not reached autolysis stage.

* Fish with high dressing yield is preferred for canning.

* The fish meat should be firm enough to withstand the normal heat processing during canning. Immediately after washing, the fish should be iced in order to avoid microbial and enzymatic spoilage.

3.2.1.3.Dressing

Dressing is a process of removing head viscera, gills and fins and the rest including skin and bones (considered as edible) go into cans. The prime quality of raw material should be available for canning. Blanching of shrimp helps in controlling the net weight of shrimp in the processed cans.

Live clams, green mussel, oysters and crab are washed, steam cooked for a few minutes to open the shell and to collect the edible portion. For some products such as crab meat, the prepared meat is packed in an orderly manner, e.g., claw meat is arranged at the top and bottom and middle layer is with body meat in the can. When the sum of countersink and tin plate thickness is deducted, net head space is obtained. It is measured after the lid is cut open. Brining removes blood, dirt, slime and other undesirable materials attached to fish. Both overfilling and under filling of cans is not acceptable. Bacterial load can be reduced by cleaning and roasting or by sanitisation using fumigants or by irradiation. This can be achieved by steaming, frying and blanching. Some fishes have to be washed, dressed and cut to required size depending on can dimension.

3.2.1.4.Brining

Brining is an operation where the dressed fish is dipped in saturated brine solution for 8-15 minutes depending on the thickness of dressed fish, brine temperature and nature of fish. Struvite crystals are glass like structures and are undesirable in canned products.

Quality of salt used for canning

* The salt used in canning should be pure and should not contain more of soluble and insoluble impurities. Further brining helps in improving the texture of meat by removing moisture.

Precooking is done to remove excess moisture and fat from the fish. The raw material used in canning can be classified as follows.

Agricultural produce - Fruits e.g.: Apple, orange, pineapple, pears, peaches, berries, cherry, mango, guava, papaya and jackfruit. The brining improves the texture of the fish.

The impurities in salt such as chlorides and sulphates of magnesium will lead to bitter taste of the product. The quantity of solid packed depends on the size of the can. Vegetables - Green Beans, carrot, peas, corn, spinach, cabbage, potato, beetroot, bamboo shoots etc.

Animal produce - Land animal e.g. Use of citric acid in blanching of shrimp is a normal practice to achieve better colouration and texture. If the above mentioned magnesium salts are present in more than 0.1% in canned fish, it results in the formation of struvite crystals. Thawing is a process of converting solid ice to water in a frozen fish. The liquid media is filled either by measuring or by weighing. Gross head space is distance between outer most point on the seam and the level of food inside the can. Under filled cans may be rejected by the consumers and quality inspectors as they are considered defective.

3.2.2.2.Methods of filling

Cans are filled with food by manual and mechanical means. It is important that every can has to be packed uniformly with respect to arrangement of fish inside the can. Frying results in reduction in moisture, firming of texture, reduction in size and improvement in taste and flavour.

Blanching is one of the precooking methods where the fish/shrimp is dipped in boiling brine containing 6-8% salt for 4-6 minutes. After precooking, fish meat looks bright and more attractive. Vegetable oil is also used in preparation of filling medium for canning. However, there will be some loss of taste and flavour components.

Precooking by steaming is done in retort for 30-45 minutes which expels moisture and fat and can be removed by draining.

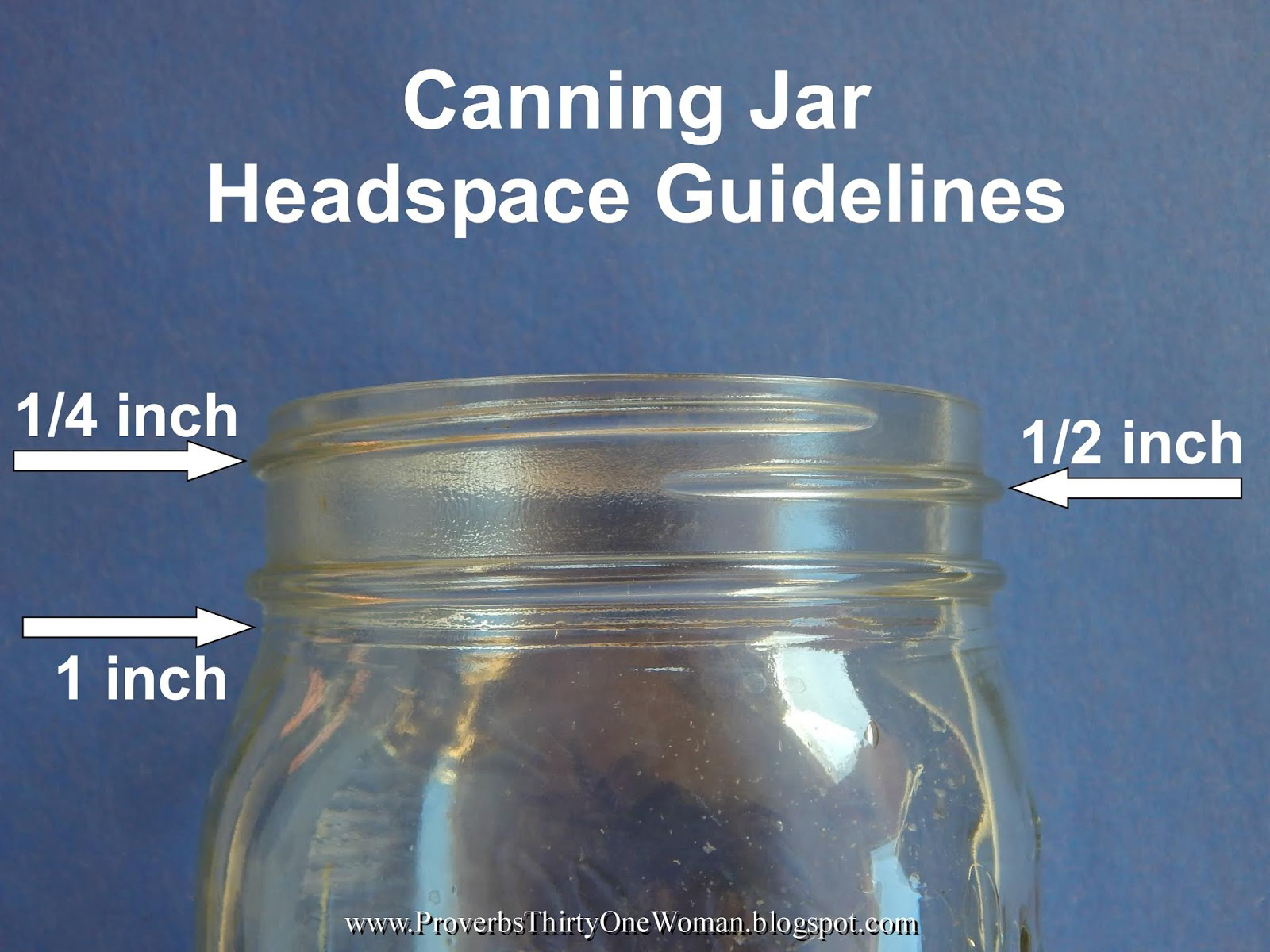

Frying is done using refined vegetable oil at a temperature of 160 to 180oC for one to three minutes. This includes countersink and thickness of the tin plate. Some vacant space is available and this is known as head space. Alternately, oleoresins and essential oils of spices are used to avoid microbial contamination.

Different unit operation in fish canning

3.2.1.1.Preparation of raw material for canning

Preparation of raw materials for canning includes steps such as cleaning, washing, sorting, dressing, trimming, size cutting, mixing, mincing, brining, blanching, precooking, shucking, frying, smoking and grading.

If the frozen fish is used for canning, thawing is an important step. Automatic machines dispense the food into cans after weighing or measuring.

For foods with soft tissues such as fish, hand filling is better as it disintegrates in machine filling due to friction or pressure. Some table salts are added with Magnesium carbonate and Calcium carbonate to maintain free flow characteristics and hence such salts have to be avoided.

3.1.4.2.Vegetable oils

For canning different types of fish, vegetable oil is used as filling medium. The product when opened should match to the description given on the label. These are available in dried form and contain high load of bacteria and spores. By this method the fish becomes firm and also the moisture content comes down. It is essential to remove blood from crab meat which otherwise results in blue discolouration.

In tuna, the precooking operation helps in easy separation of dark and light meat. Fish meat with dark pigments will discolor the final product.

3.1.3.Portions of fish used for canning

Generally small pelagic fishes like mackerel, sardine and anchovies are canned with skin and bones; hence the skin should have lustrous shining appearance.

Meat chunks of large fishes like tuna, seer fish and catfish are canned.

Only the edible portions of shrimps, clams, oysters, mussels and crabs are used for canning.

3.1.4.Ingredients for canning

Other than raw material, the important ingredients used in canning of fish are,

* Salt

* Oil

* Additives like spices (other ingredients)

The quality of ingredients used for canning of fish will have effect on the final quality of the product.

3.1.4.1.Salt

Salt is used in the preparation of brine and the concentration of salt used may vary from 6-8% to saturated salt solution. Sometimes, heads and small fins are not removed. Brine is used for dip treatment to dressed fish prior to canning, blanching of peeled and deveined prawns (6 to 8% boiling brine) and as filling medium (1-3%) salt in fish cans. Filling the cans beyond the acceptable limits not only cause losses to the manufacturer but also creates several other problems. It is important to keep the fish in chilled condition during all pre-processing operations.

3.2.1.2.Washing

Washing of fish has to be done using adequate quantity of chilled water (either by using ice or by refrigeration). The fish meat should not disintegrate after canning.

* The colour of the meat should be light or white. Refined cottonseed oil, groundnut oil, sunflower oil and soybean oil are primarily used.

Quality of oil used for canning,

* Free from moisture content is suitable.

* Specific gravity should be between 0.9-0.92.

* The oil should have less of unsaturated (iodine value should be less) fatty acids.

3.1.4.3.Other ingredients

In order to enhance taste and flavour of canned products spices such as chilli, pepper, cardamom, cumin, ginger etc are used. For other marine products hand filling of fish is done and the filling medium is dispensed using machines.

3.2.2.3.Precautions to be taken during filling

* Labeling of the product should match the content of the can. Filling machines may be automatic or semiautomatic type. The details such as gross weight, net weight, type of fish, type of filling media, size of pieces and nutritional weight, net weight of solids, number of pieces, size of pieces, type of filling media and nutritional value should be mentioned on the label of the can. Thawing is done either in air or in running water till all ice of the fish melts.

If the fresh fish is used for canning it should be chilled immediately. What is unit operation?

In food processing, the different steps involved in the preparation of processed foods is termed as unit operation. This will ensure consumer appeal.

3.2.2.4.Problems caused by over filling of cans

* Permanent distortion of can ends at end of retorting.

* Produces flipper or springer in cans packed with acid products.

* Loss of vacuum and less shelf life.

* Slower heat penetration into the cans leading to under processing or process failure.

* Over packing causes problems during seaming.

* Over packing causes economic loss.

3.2.2.4.1.Head space in cans

In any food can, food and the filling medium do not occupy the complete space available inside the can. Also when solids without liquid medium are packed, air should not be entrapped at the bottom of the can.

* All the cans have to be packed uniformly with solids and liquids so that the head space is also uniform.

* The filling of the cans should be uniform for a particular type of canned fish. The amount of solid material packed into the can is referred as solid pack. The typical example for unit operations are washing, dressing, filling, chilling freezing, retorting and quality assurance etc.,

3.1.1.Raw materials and other ingredients for canning

The purpose of canning is for long term preservation of food stuffs and hence raw material is an important requirement of the industry. Hence care and accuracy of filling is required.

* Overfilling of solids or liquids should as it leads unsatisfactory thermal processing or under processing or thermal process failure.

* Inconsistency in the product with reference to appearance, color and quantity should be avoided.

* Care should be taken not to include undesirable and foreign materials such as dirt, shell, pieces of legs, hair or housefly or other insect parts.

0 Comments